Detecting Industrial Potato Chips Defects with Machine Learning Methods Using Deep Features

DOI:

https://doi.org/10.58190/imiens.2024.100Keywords:

potato chips, computer vision, defective products, convolutional neural networkAbstract

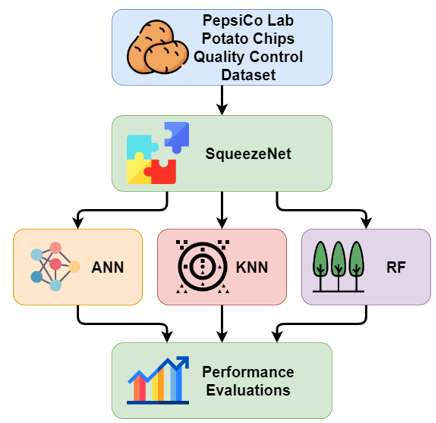

Detection of production defects in industrial foods is vital to protect consumer health. Early detection of these errors can minimize the economic losses of manufacturers by reducing the costs of recalls and production stoppages. Additionally, continuous monitoring and improvement of product quality can increase brand reliability and customer satisfaction. Image processing can detect product defects, minimize human error and increase efficiency by performing uninterrupted inspection on the production line. Based on these reasons, this study aimed to detect potato chip errors with image processing. PepsiCo Lab Potato Chips Quality Control image dataset was used in the study. There are two classes in the dataset: defective and not defective. There are 967 images in total. SqueezeNet Convolutional Neural Network (CNN) architecture was used to extract the features of the images. With this architecture, 1000 features obtained for each image were classified with Artificial Neural Network (ANN), K Nearest Neighbor (KNN), Random Forest (RF) machine learning methods. As a result of the classifications, 0.986 classification accuracy was obtained from the ANN model, 0.927 from the KNN model, and 0.962 from the RF model. F1 Score, precision, recall and specificity metrics were used to compare the models in detail. According to the data obtained from the experimental results, it is predicted that the proposed feature extraction and classification models can detect industrial production errors occurring in potato chips.

Downloads

References

Smith, P.G. and P.G. Smith, An introduction to food process engineering, Springer US, 2011. p. 1-3, Online ISBN 978-1-4419-7662-8. DOI: 10.1007/978-1-4419-7662-8_1

Augustin, M.A., et al., Role of food processing in food and nutrition security. Trends in Food Science & Technology, 2016. 56: p. 115-125. DOI: 10.1016/j.tifs.2016.08.005

Patel, K.K., et al., Machine vision system: a tool for quality inspection of food and agricultural products. Journal of food science and technology, 2012. 49: p. 123-141. DOI: 10.1007/s13197-011-0321-4

Cubero, R. and I.V. Hollar, Equity and fiscal policy: income distribution effects of taxation and social spending. Economic Progress and Reforms, 2008: p. 62.

Alva, A., et al., Improving nutrient-use efficiency in Chinese potato production: experiences from the United States. Journal of Crop Improvement, 2011. 25(1): p. 46-85. DOI: 10.1080/15427528.2011.538465

López, A., et al., A review of the application of near-infrared spectroscopy for the analysis of potatoes. Journal of agricultural and food chemistry, 2013. 61(23): p. 5413-5424. DOI: 10.1021/jf401292j

Peña, R., et al., Authentication of Galician (NW Spain) quality brand potatoes using metal analysis. Classical pattern recognition techniques versus a new vector quantization-based classification procedure. Analyst, 2001. 126(12): p. 2186-2193. DOI: 10.1039/B107114A

Mahajan, S., A. Das, and H.K. Sardana, Image acquisition techniques for assessment of legume quality. Trends in Food Science & Technology, 2015. 42(2): p. 116-133. DOI: 10.1016/j.tifs.2015.01.001

Barbedo, J.G.A., A review on the main challenges in automatic plant disease identification based on visible range images. Biosystems engineering, 2016. 144: p. 52-60. DOI: 10.1016/j.biosystemseng.2016.01.017

Zareiforoush, H., et al., Potential applications of computer vision in quality inspection of rice: a review. Food engineering reviews, 2015. 7(3): p. 321-345. DOI: 10.1007/s12393-014-9101-z

Villalba-Diez, J., et al., Deep learning for industrial computer vision quality control in the printing industry 4.0. Sensors, 2019. 19(18): p. 3987. DOI: 10.3390/s19183987

Pedreschi, F., D. Mery, and T. Marique, Quality evaluation and control of potato chips, in Computer vision technology for food quality evaluation. 2016, Elsevier. p. 591-613. DOI: 10.1016/B978-0-12-802232-0.00022-0

Gencturk, B., et al., Detection of hazelnut varieties and development of mobile application with CNN data fusion feature reduction-based models. European food research and technology, 2024. 250(1): p. 97-110. DOI: 10.1007/s00217-023-04369-9

Cinar, I., et al. Identification of corneal ulcers with pre-trained AlexNet based on transfer learning. in 2022 11th Mediterranean conference on embedded computing (MECO). 2022. IEEE. DOI: 10.1109/MECO55406.2022.9797218

Feyzioglu, A. and Y.S. Taspinar, Beef quality classification with reduced E-nose data features according to beef cut types. Sensors, 2023. 23(4): p. 2222. DOI: 10.3390/s23042222

Kursun, R., et al. Flower recognition system with optimized features for deep features. in 2022 11th Mediterranean Conference on Embedded Computing (MECO). 2022. IEEE.

Koklu, M., et al. Identification of sheep breeds by CNN-based pre-trained InceptionV3 model. in 2022 11th Mediterranean Conference on Embedded Computing (MECO). 2022. IEEE. DOI: 10.1109/MECO55406.2022.9797214

Dağlı, E., M. Büber, and Y.S. Taspınar, Detection of accident situation by machine learning methods using traffic announcements: the case of metropol Istanbul. International journal of applied mathematics electronics and computers, 2022. 10(3): p. 61-67. DOI: 10.18100/ijamec.1145293

Isik, M., et al., Automated classification of hand-woven and machine-woven carpets based on morphological features using machine learning algorithms. The Journal of The Textile Institute, 2024: p. 1-10.

Kishore, B., et al., Computer-aided multiclass classification of corn from corn images integrating deep feature extraction. Computational Intelligence and Neuroscience, 2022. 2022(1), 2062944. DOI: 10.1155/2022/2062944

Butuner, R., et al., Classification of deep image features of lentil varieties with machine learning techniques. European Food Research and Technology, 2023. 249(5): p. 1303-1316. DOI: 10.1007/s00217-023-04214-z

Isik, H., et al., Maize seeds forecasting with hybrid directional and bi‐directional long short‐term memory models. Food Science & Nutrition, 2024. 12(2): p. 786-803. DOI: 10.1002/fsn3.3783

Unal, Y., et al., Application of pre-trained deep convolutional neural networks for coffee beans species detection. Food Analytical Methods, 2022. 15(12): p. 3232-3243. DOI: 10.1007/s12161-022-02362-8

Dogan, M., et al., Dry bean cultivars classification using deep cnn features and salp swarm algorithm based extreme learning machine. Computers and Electronics in Agriculture, 2023. 204: p. 107575. DOI: 10.1016/j.compag.2022.107575

Kursun, R., K.K. Bastas, and M. Koklu, Segmentation of dry bean (Phaseolus vulgaris L.) leaf disease images with U-Net and classification using deep learning algorithms. European Food Research and Technology, 2023. 249(10): p. 2543-2558. DOI: 10.1007/s00217-023-04319-5

Singh, D., et al., Classification and analysis of pistachio species with pre-trained deep learning models. Electronics, 2022. 11(7): p. 981. DOI: 10.3390/electronics11070981

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Intelligent Methods In Engineering Sciences

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.