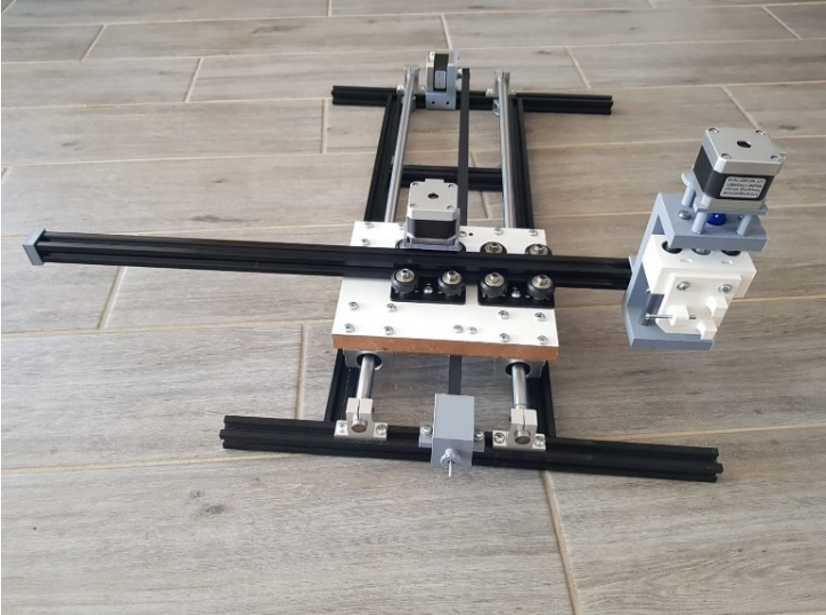

Welding Robot Design with Machine Learning Based Intelligent Vision System

DOI:

https://doi.org/10.58190/imiens.2023.12Keywords:

Robotic welding, artificial intelligence, machine learning, deep learning, welding robot designAbstract

The use of welding technologies in the manufacturing sector plays a very important role and increases its popularity thanks to developing technologies. Welding technologies are used in almost every field where production takes place, and the speed and efficiency of welding technologies have increased in these sectors in recent years. The fact that artificial intelligence techniques are at the forefront and the efficient use of these techniques together with sensors has led to development in welding technology. Thus, welding robots emerged with the support of robots with artificial intelligence techniques, and adaptive systems that can adapt to different types of workpieces working autonomously in the manufacturing sector are shaping the sector. Despite these developments, non-autonomous systems are still used today by teaching the welding points to the robots by the operators. Along with the concept robotic system to be designed and implemented within the scope of this study, it is planned to determine the welding trajectory autonomously with artificial intelligence techniques, and to perform the welding process by following the welding trajectory by the robot.

Downloads

References

M. Vasilev, C. MacLeod, W. Galbraith, Y. Javadi, E. Foster, G. Dobie, G. Pierce, A. Gachagan, Non-contact in-process ultrasonic screening of thin fusion welded joints, J. Manuf. Process. 64 (2021) 445–454. https://doi.org/10.1016/j.jmapro.2021.01.033.

Y. Wu, B. Gao, J. Zhao, Y. Wang, Z. Liu, J. Chen, Y. Ying, G.Y. Tian, Weld Crack Detection Based on Region Electromagnetic Sensing Thermography, IEEE Sens. J. 19 (2019) 751–762. https://doi.org/10.1109/JSEN.2018.2868867.

Y. Gao, J. Xiao, G. Xiong, H. Zhang, Research on the deviation sensing of V-groove weld seam based on a novel two channel acoustic sensor, Int. J. Adv. Manuf. Technol. 119 (2022) 5821–5837. https://doi.org/10.1007/s00170-021-08454-9.

G. Li, Y. Hong, J. Gao, B. Hong, X. Li, Welding seam trajectory recognition for automated skip welding guidance of a spatially intermittent welding seam based on laser vision sensor, Sensors (Switzerland). 20 (2020) 1–19. https://doi.org/10.3390/s20133657.

Y. Zou, J. Chen, X. Wei, A calibration optimization method for a welding robot laser vision system based on generative adversarial network, IEEE Trans. Instrum. Meas. 70 (2021). https://doi.org/10.1109/TIM.2021.3113950.

J. Yu, Real-Time Weld Quality Prediction Using a Laser Arc Welding, (2020).

R. Du, Y. Xu, Z. Hou, J. Shu, S. Chen, Strong noise image processing for vision-based seam tracking in robotic gas metal arc welding, Int. J. Adv. Manuf. Technol. 101 (2019) 2135–2149. https://doi.org/10.1007/s00170-018-3115-2.

R. Xiao, Y. Xu, Z. Hou, C. Chen, S. Chen, An adaptive feature extraction algorithm for multiple typical seam tracking based on vision sensor in robotic arc welding, Sensors Actuators, A Phys. 297 (2019) 111533. https://doi.org/10.1016/j.sna.2019.111533.

G. Zhang, Y. Zhang, S. Tuo, Z. Hou, W. Yang, Z. Xu, Y. Wu, H. Yuan, K. Shin, A novel seam tracking technique with a four-step method and experimental investigation of robotic welding oriented to complex welding seam, Sensors. 21 (2021). https://doi.org/10.3390/s21093067.

Y. Zou, T. Chen, X. Chen, J. Li, Robotic seam tracking system combining convolution filter and deep reinforcement learning, Mech. Syst. Signal Process. 165 (2022) 108372. https://doi.org/10.1016/j.ymssp.2021.108372.

X. Li, X. Li, M.O. Khyam, S.S. Ge, Robust Welding Seam Tracking and Recognition, IEEE Sens. J. 17 (2017) 5609–5617. https://doi.org/10.1109/JSEN.2017.2730280.

H. Shen, T. Lin, S. Chen, L. Li, Real-time seam tracking technology of welding robot with visual sensing, J. Intell. Robot. Syst. Theory Appl. 59 (2010) 283–298. https://doi.org/10.1007/s10846-010-9403-1.

H. Ma, S. Wei, Z. Sheng, T. Lin, S. Chen, Robot welding seam tracking method based on passive vision for thin plate closed-gap butt welding, Int. J. Adv. Manuf. Technol. 48 (2010) 945–953. https://doi.org/10.1007/s00170-009-2349-4.

Y. Zou, X. Wei, J. Chen, M. Zhu, H. Zhou, A High-Accuracy and Robust Seam Tracking System Based on Adversarial Learning, IEEE Trans. Instrum. Meas. 71 (2022). https://doi.org/10.1109/TIM.2022.3186085.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Intelligent Methods In Engineering Sciences

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.